The machine is completely made of stainless steel and anodized aluminum and is suitable for working in wet environments.

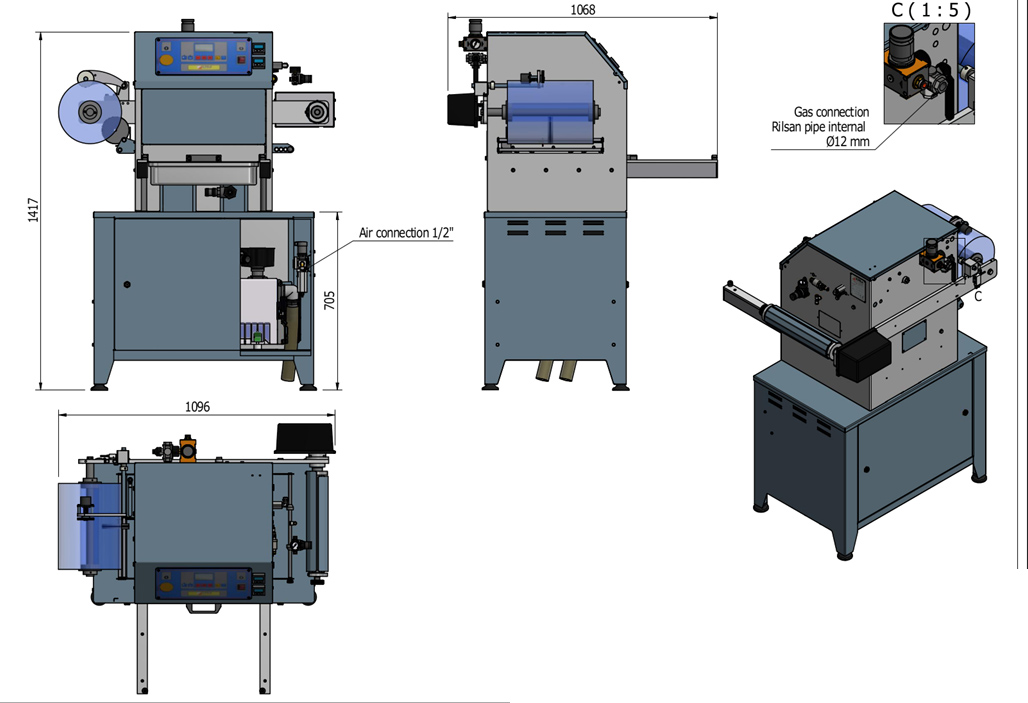

Includes a large Busch Vacuum Pump which can be found in the stainless steel base of the machine.

Cleaning and maintenance are easy and quick, and changeovers can be performed in under 5 minutes.

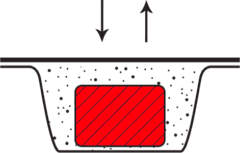

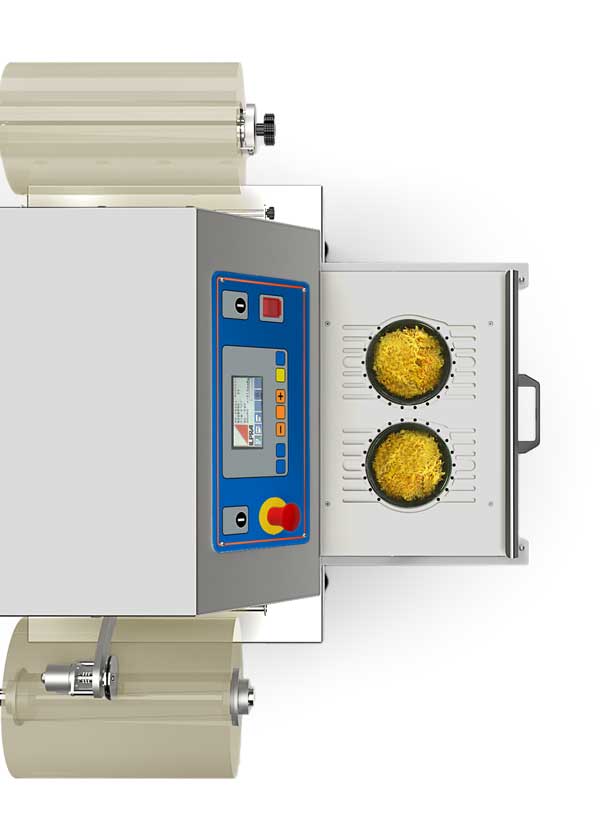

Speeds vary depending on each application, however a typically VSP application can produce about 3 cycles per minute (multiplied by the quantity of impressions). With a standard (No. 3) tray, we will achieve a 2 impression tooling set.

Tested and approved for HPP (High Pressure Processing) quality seals.

***ASK ABOUT OUR EQUIPMENT FINANCING SOLUTIONS, INCLUDING 0% FOR QUALIFIED CUSTOMERS***

*All the companies of the ILPRA Group operate according to ISO 9001:2008 compliance and their organization of production is fully internal. Before delivering, each machine undergoes the scrutiny of strict internal test procedures, carried out with the packaging materials received from customer. This procedure verifies that the product is in compliance with both the customer and the regulations in force with Ilpra.