| SOLLAS SX60 |

| Size range (in mm) |

min. standard |

min. adapted* |

max. standard |

max. adapted* |

| Length (L) |

40 |

– |

300 |

360 |

| Width (W) |

40 |

20 |

225 |

265 |

| Height (H) |

16 |

7 |

96 |

125 |

| Maximum output |

60 strokes per minute |

| SOLLAS SX80 |

| Size range (in mm) |

min. standard |

min. adapted* |

max. standard |

max. adapted* |

| Length (L) |

40 |

– |

300 |

336 |

| Width (W) |

40 |

20 |

175 |

– |

| Height (H) |

16 |

7 |

66 |

– |

| Maximum output |

80 strokes per minute |

*Modifications in one dimension may limit the size range in the other dimensions or affect the machine output

| DETAILED TECHNICAL SPECIFICATIONS |

| Sollas SX |

60 |

80 |

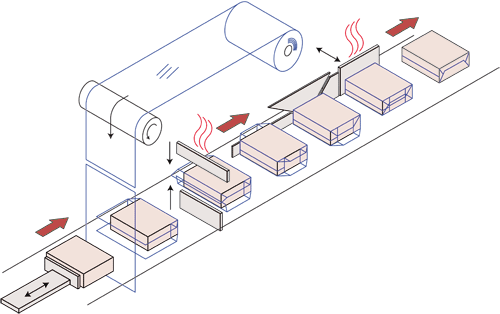

| packaging style |

overwrapping |

overwrapping |

| product size range (LxWxH) |

| L |

40 – 300 mm |

40 – 300 mm |

| W |

40 – 225 mm |

40 – 175 mm |

| H |

16 – 96 mm |

16 – 66 mm |

| size range adapted (LxWxH); |

| L |

40 – 360 mm |

40 – 336 mm |

| W |

20 – 265 mm |

20 – 175 mm |

| H |

7 – 125 mm |

7 – 66 mm |

| output max. |

60 / minute |

80 / minute |

| size change time |

5 – 15 minutes |

5 – 15 minutes |

| film width |

50 – 435 mm |

50 – 435 mm |

| film length |

50 – 850 mm |

50 – 850 mm |

| film length adapted |

50 – 850 mm |

50 – 850 mm |

| filmroll diameter max. |

400 mm |

400 mm |

| packaging material |

PP/coated paper (20 micron and up) |

| machine lay out |

HL / HR / LL / DIL |

HL / HR / LL / DIL |

| infeed height |

900 mm +/- 20 |

900 mm +/- 20 |

| outfeed height |

900 mm +/- 20 |

900 mm +/- 20 |

| air consumption |

4 nl / stroke |

4 nl / stroke |

| air pressure |

6 Bar |

6 Bar |

| power consumption |

2,5 kW |

2,5 kW |

| machine weight (net) |

1200 kg |

1200 kg |

| machine dimension |

see drawing |

| machine colour |

RAL 9006 |

RAL 9006 |

| options |

teartape applicator, printmark registration, film slitting, castors, various infeed systems, stainless steal cladding, precise vacuum film feed system, optimal (spot) seal positioning by Individual Product Transport system (IPT), servo controlled pusher, central lubrication, 2nd filmroll, splicing unit, felt on machine |

| drive |

cam / servo |

cam / servo |

| control |

PLC |

PLC |