Your First Source for Tray Sealing and Fill Sealing, Modified Atmosphere Packaging Equipment.

ILPRA is the top Tray Sealing brand globally. Our tray sealing machines provide solutions for small, medium and large-scale production operations and are used primarily for:

- Shelf-life extension

- Reduction in packaging costs

- Containment of prepackaged foods

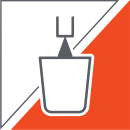

From small delis to large-scale food manufacturing, we have the ability to design and tailor a Fill Seal machine suitable for all production levels.

- Made from 304/316 stainless steel

- Washdown friendly – IP65 protected

- Foil or film seal capable

Most models can perform the following packaging types:

-

Sealing

Only -

Modified

Atmosphere

Packaging (MAP) -

Vacuum Only, or

Vacuum Skin Packaging

(VSP)

All units however are tested and approved of HPP (High Pressure Pasteurization), from a seal quality standpoint.

Let’s discuss the basic packaging types in more detail.

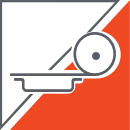

Tray Sealing Only and

Modified Atmosphere Equipment

As the name implies, each machine within the ILPRA Tray Sealing lineup can perform both:

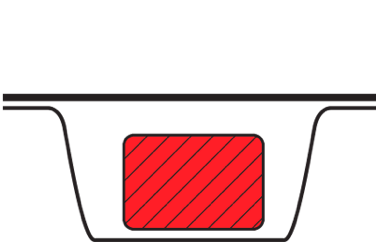

Sealing only

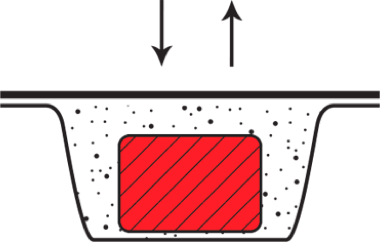

Modified Atmosphere Packaging (MAP)

This is simply a matter of changing a setting within the control panel of the machine.

Sealing only applications typically include frozen entrees or produce.

Whereas the Modified Atmosphere Packaging applications can be anything fresh, such as: pasta, meat, poultry, hummus, and dairy.

In the Modified Atmosphere Packaging process we extract all the air within the chamber, before injecting the correct gas type/mixture that your application calls for. We inject by the means of our patented PROGAS method.

With this patented method, we only use a small bit of vacuum before injecting the gas into the tray, rather than wasting gas and filling the entire chamber, like other competitors.

In conclusion, we increase speeds, and decrease gas consumption while achieving the best possible shelf life for your product.

Vacuum Only

Vacuum Only applications are typically performed when a customer is considering using High Pressure Pasteurization (HPP).

HPP is a cold pasteurization technique by which products, already sealed in its final package, is introduced into a vessel and subjected to a high level of pressure (87,000psi) transmitted by water.

In this application, the ILPRA Tray Sealer needs to extract as much air out of the packaging as possible, to help ensure the final package will perform under the HPP process. If there is too much air within prior to HPP, the package will fail.

Vacuum Skin Packaging (VSP)

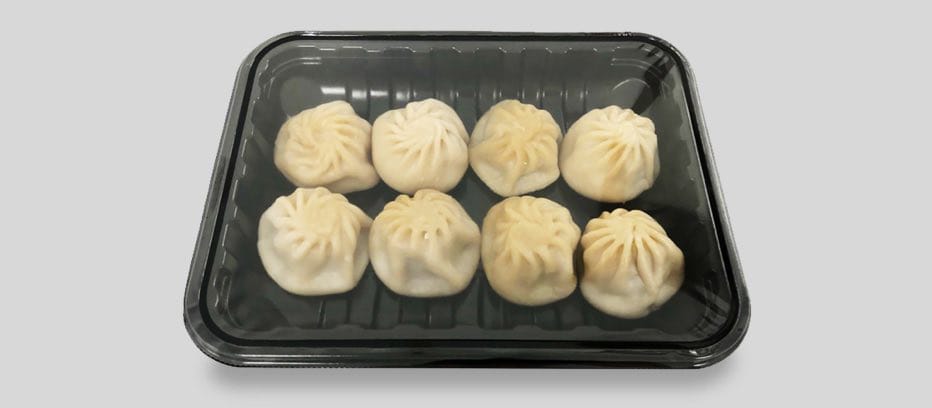

Vacuum Skin Packaging is typically seen in the following industries:

- Frozen/ Fresh ready meal,

- Fresh beef, poultry, and seafood (with 10K ‘breathable’ film).

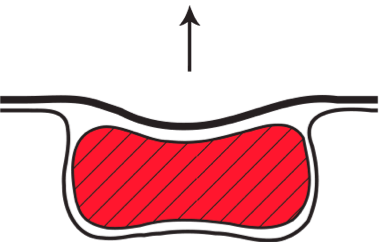

In this application, the film is heated, stretched, and then vacuumed, pulling the film tightly to the product. Once the film is vacuumed in full, the film takes the complete shape of the product, and heat-sealed to the tray.

This provides the following advantages:

- Secures the product in place,

- Increases the shelf appeal to consumer,

- Prolongs shelf life and sustains the highest quality of product by preserving flavor

Accessories

As the exclusive North American supplier of ILPRA equipment we also offer a variety of accessories to assist in making the tray sealing and modified atmosphere packaging equipment run more effectively and efficiently.

Everything from – Automatic tray placing systems (e.g. Denestors) with high capacity storage, changeover devices, settling “shaker” systems for infeeds, merging and diverging systems, and depositing devices (and more…), we have you covered.

Information is available today

We are here to help you answer questions like:

- Which machine works best for you?

- Which application offers the easiest maintenance and changeover capabilities?

The answers depend solely on what production needs you demand.

Whereas large scale food service companies may find modified atmosphere packaging a suitable solution to seafood processing, family-owned businesses who process poultry may find basic tray sealing equipment sufficient.

There’s no shortage of technical documentation available to assist you, but talking to an expert will be easier and painless.

To learn more, or to discuss potential machine purchases, reach out by phone or email.

North American Flexible Packaging Film Converter/Distributor

About RTG Films

visit rtgfilms.comRTG Films is an AIB Certified ("food safe") division which specializes in film Converting / Distributing of Flexible Packaging Films. Since our inception in 1995 in Montgomeryville PA, we have been providing our customers with premium Flexible Films at the most reasonable cost. Please visit our website to learn more about RTG Films.