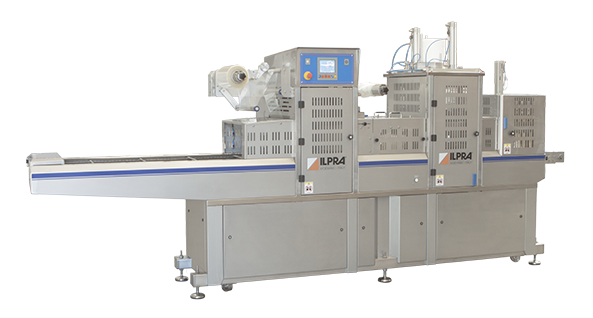

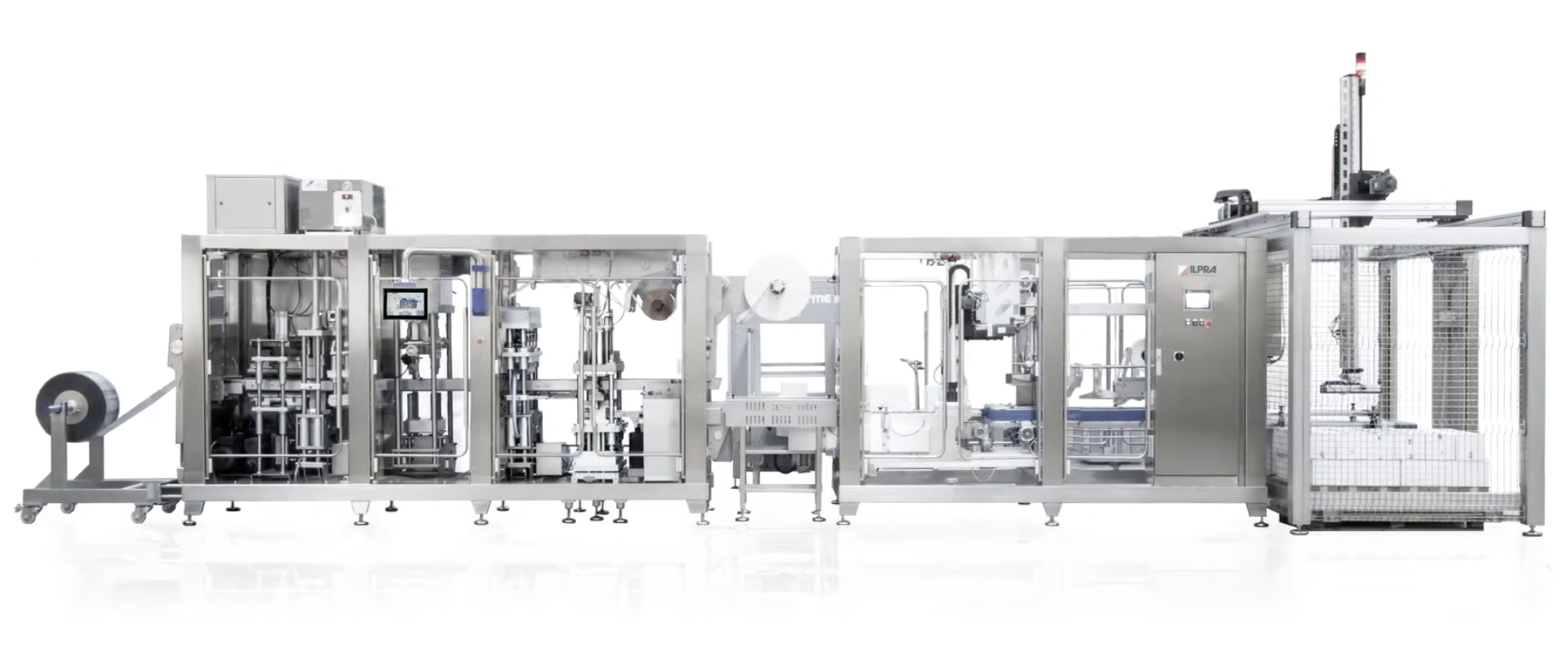

Fill sealing machines do as their name implies: fill cups or trays with product, such as yogurt, soups, and other liquid-based foods, then seal these cups with a specific thickness of plastic film or foil lid. Our filling machines have the ability (unlike other brands) to perform a true MAP (Modified Atmosphere Packaging), and not simply gas flush. All parameters of the machines can be set and saved through the machines Siemens PLC. All filling machines utilize the highest quality stainless steel (304/316) and are capable of running a vast array of products, by simply changing the depositing station (if needed). All our fill sealing machine produces HPP Quality seals.

Numerous fill sealing applications are available depending on your budget and production needs.