Modified Atmosphere Packaging (MAP):

Modified Atmosphere Packaging (MAP):

This Tray Sealing process can take place in either, Gas Flush or Vacuum Gas form. Although each process has pros and cons, in either case the goal is simple, remove/reduce the gas (often Oxygen) that spoils food and replace it with a MAP Gas Mixture (often Nitrogen and Carbon Dioxide) at an acceptable oxygen residual level for highest preservation of the food. By reducing the amount of Oxygen within the package we delay the spoilage of the product. Having Oxygen within allows the growth of microorganisms and bacteria, in addition to causing the food to lose its “fresh look” much sooner than a MAP Pack often would. As the demand for extending the shelf life of Fresh (not frozen) items grow in popularity in a retail environment, the demand for Modified Atmosphere Packaging is skyrocketing.

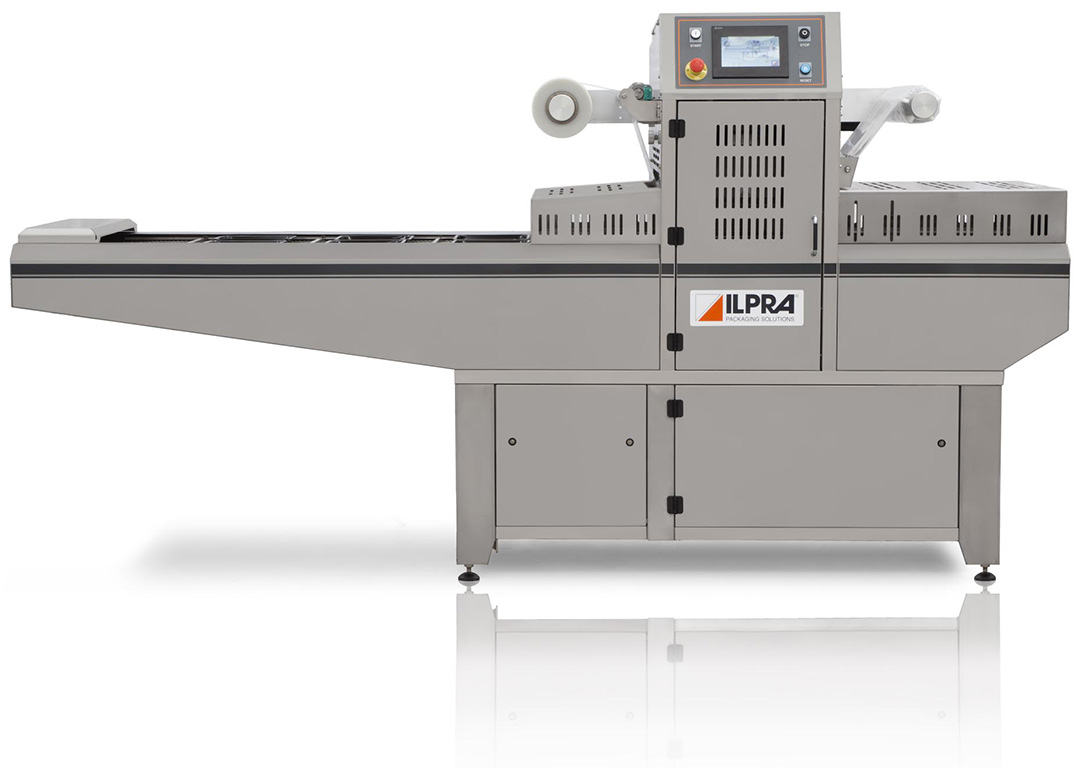

As a popular example, Fresh Meal Delivery is one of the fastest growing markets in the US and has grown to over 2 Billion Dollars in sales in 2022. Meal Prep companies throughout the US start their businesses with the common top and bottom snap-on lid system, as the cost for expensive Tray Sealing machinery is not required. However, as Meal Prep companies grow, they quickly realize that in order to expand their delivery reach geographically, they MUST extend the shelf life, with the desire of delivering fresh meals. This is where ILPRA Tray Sealers strive, and the businesses consider either entry level models; Foodpack ENERGY or SPEEDY.

The advantages to this style of packaging are:

- Extremely versatile for various applications

- Excellent shelf-life extension compared to “Snap on Lids”

- Convenient to customers

- Economical application from equipment standpoint

- Uses ILPRA Patented PROGAS Technology

- High throughput level solutions on equipment end.