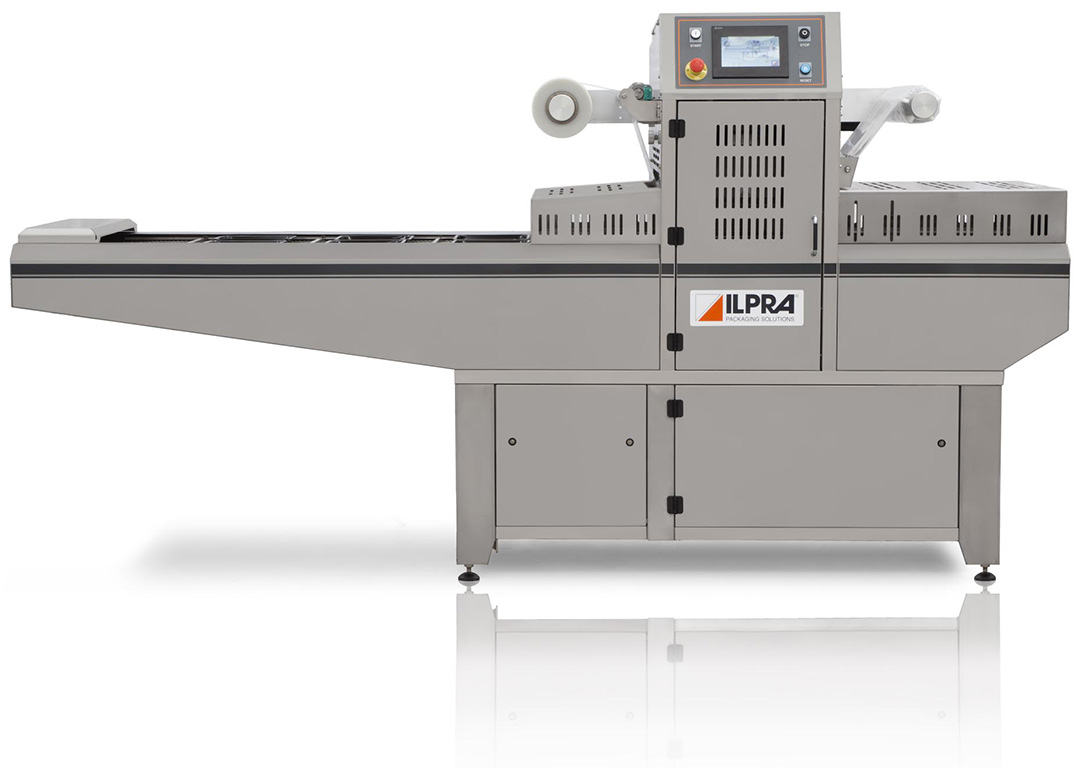

This model is manufactured in excess of 100 every year, and is designed to meet the highest constructive Standards.

The machine is mainly constructed in stainless steel, Class protection IP65, and is conceived to be a cost-effective model. Just few of its strongest points: reliability, easy cleaning and maintenance, a simplified software for working parameters, many available accessories which make the machine fully customized. ILPRA improves the Speedy performance with innovative technology to obtain either low consumptions or capacity increase. For instance the Progas technology, as standard on the FOODPACK range, will reduce the gas consumption of 40% than traditional solutions, while the mechanical Speedy version avoid the cost of compressed air and reduce the maintenance ones.

*Tested and approved for HPP (High Pressure Processing) quality seals.

This machine serves the following industries:

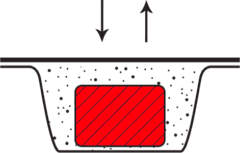

- Seafood Processing Plants (NOTE: this machine is VSP capable with 10K Film)

- Meat and Poultry

- Contract Packaging (Co-Packing)

- Produce Processing Plants

- Pasta

- Ready Meals – Entrees

- Baked Goods

- Hummus, Salsa, Dips, and much more…

Tested and approved for HPP (High Pressure Processing) quality seals and 10K Skin/VSP Film, to plastic trays and/or boards.

***ASK ABOUT OUR EQUIPMENT FINANCING SOLUTIONS, INCLUDING 0% FOR QUALIFIED CUSTOMERS***

*All the companies of the ILPRA Group operate according to ISO 9001:2008 compliance and their organization of production is fully internal. Before delivering, each machine undergoes the scrutiny of strict internal test procedures, carried out with the packaging materials received from customer. This procedure verifies that the product is in compliance with both the customer and the regulations in force with Ilpra.