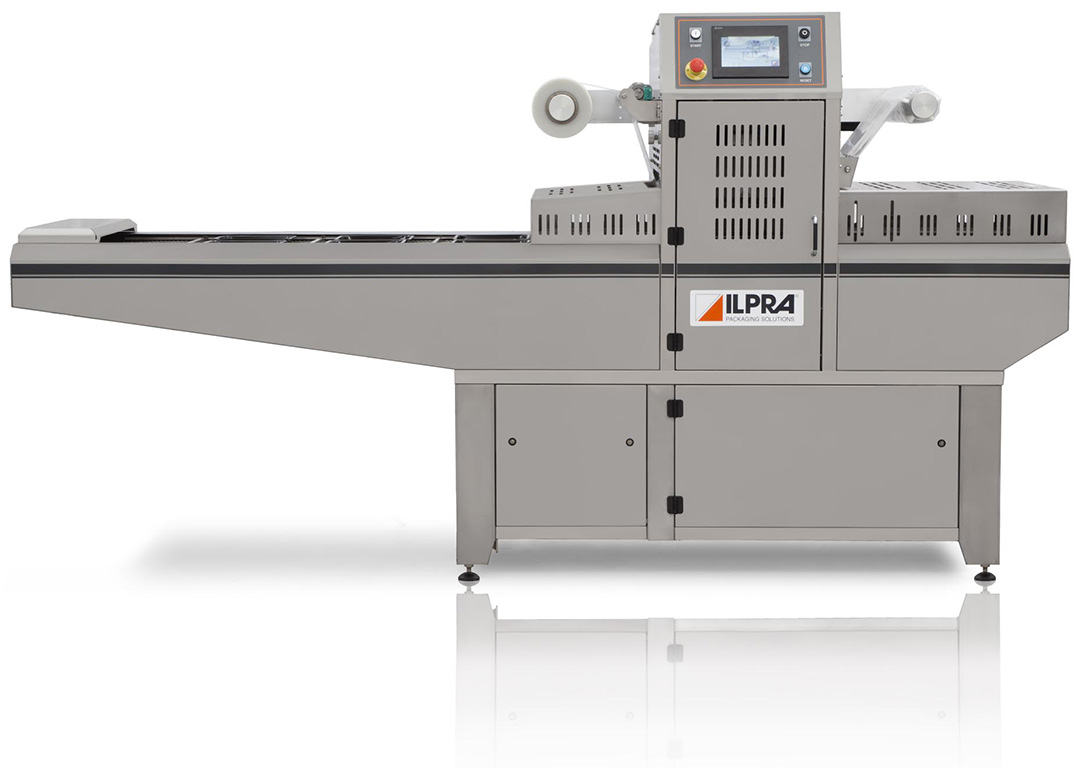

ILPRA Tray Sealers

Designed to streamline production of pre-packaged foods for various retail applications, the ILPRA line of tray sealer machines allow the packaging and sealing of various consumables in pre-formed trays by means of sealing with modified atmosphere packaging (MAP) and various Skin (VSP) operations.

Set entirely in stainless steel featuring an automatic film unwinder, ILPRA tray packaging machines offer performance in high-volume manufacturing settings and smaller operations alike. Whether speed and or budget is a concern, we will have the right machine just for you.

There are three major types of tray sealer machines that ILPRA specializes in: