Blog

-

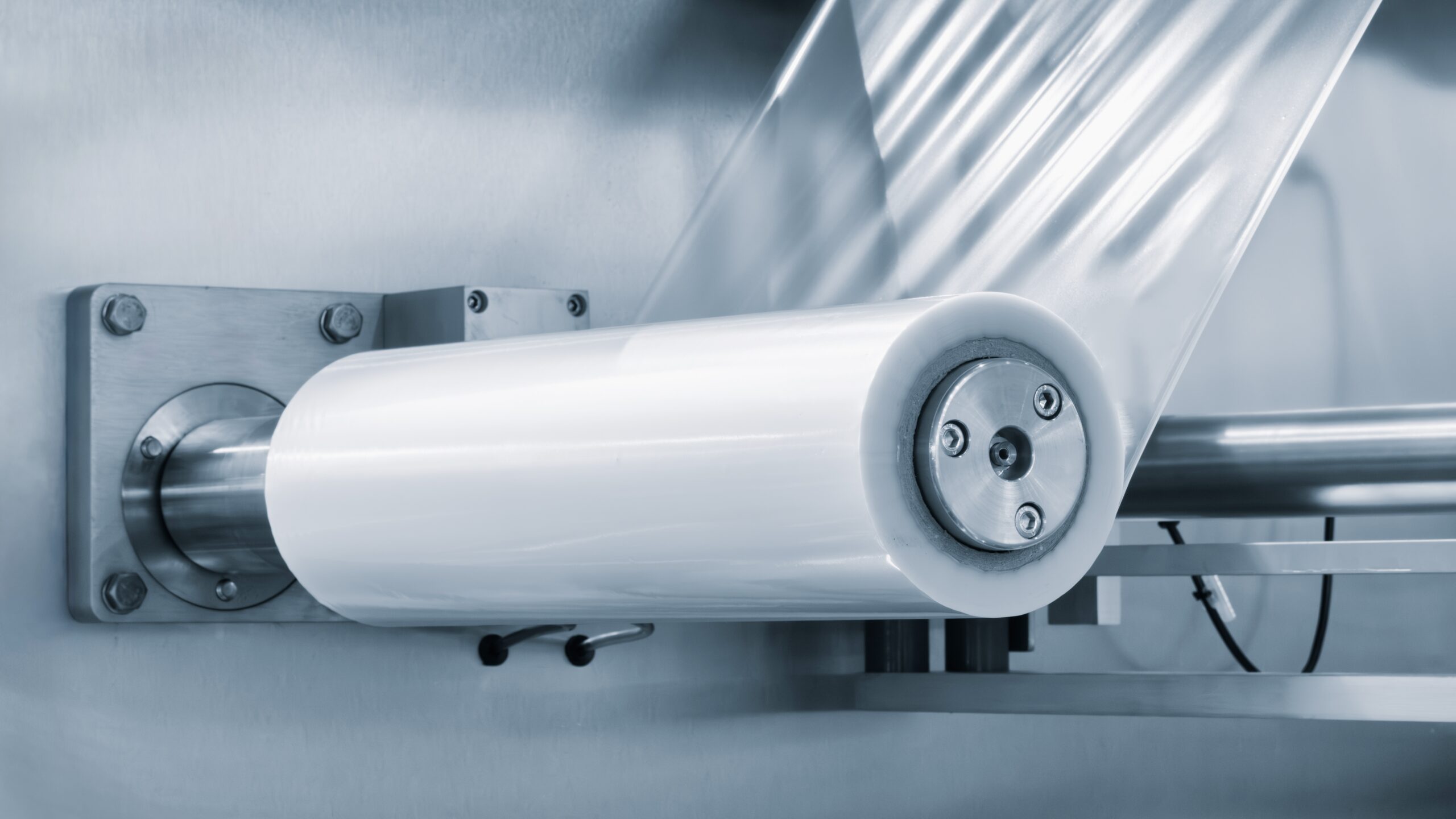

Troubleshooting Seal Integrity: A Guide to High-Speed Overwrapping Maintenance

In the world of high-volume manufacturing, the overwrap from an overwrapping machine is the final handshake between your product and the consumer. It provides the tamper-evident security, the “freshness” barrier, and the premium aesthetic that brands demand. However, when you’re pushing throughput at high speeds, the margin for error shrinks to microns. For maintenance teams […] Learn More

-

Speed Meets Sustainability: Optimizing Overwrapping Machines for Bio-Based Films

The industrial packaging landscape is undergoing a seismic shift. For decades, the primary metrics for success were simple: speed and cost. However, as global regulations tighten and consumer demand for “green” products reaches a fever pitch, a new titan has entered the room: Sustainability. Sustainability is currently the fastest-growing search category in industrial packaging. For […] Learn More

-

The ROI of Precision: Overwrapping vs. Shrink Wrapping for Premium Packaging

In the world of high-end manufacturing, your packaging is your first handshake with the consumer. Whether it is a luxury fragrance, a premium pharmaceutical, or high-end confectionery, the unboxing experience begins before the box is even opened. For many brands, the choice boils down to two primary methods: Overwrapping and Shrink Wrapping. On the surface, […] Learn More

-

Plastic Food Sealing by Roberts Technology Group, Inc.

Freshness defines success in the modern food industry. Customers demand meals that taste as if the chef just prepared them, regardless of when or where they eat. Packaging plays a massive role in meeting this high standard for quality and safety. A machine for sealing plastic in a food box serves as a critical asset […] Learn More

-

Maximizing Production Efficiency: The Sollas Advantage for Modern Manufacturers

In the high-stakes world of secondary packaging, the difference between a market leader and a struggling operation often comes down to a matter of seconds. As global supply chains tighten and consumer demand for “shelf-ready” aesthetics grows, manufacturers are under immense pressure to deliver more products, faster, without compromising on quality. At RTG Packaging, we […] Learn More

-

How Fill Seal Machines Handle Temperature-Sensitive Products

The yogurt hits the cup at precisely 42 degrees. The seal forms at 350 degrees for exactly 1.2 seconds. Between these two moments lies the entire challenge of packaging temperature-sensitive products without compromising quality, texture, or shelf life. Knowing how the right machines accomplish this is integral to making sure your goods are filled and […] Learn More

-

Elevating Cosmetics Packaging: How Overwrapping Machines Create the Ultimate Premium Finish

The first moment a customer picks up a beauty product defines their relationship with the brand. If the packaging feels loose or looks cheap, the perceived value of the formula inside drops instantly. This is the reality of the cosmetics aisle. Shoppers judge the quality of a face cream or perfume by the precision of […] Learn More

-

Vacuum Sealing vs. MAP: Which Method Keeps Your Food Fresh Longer?

You’ve just invested in premium ingredients, perfected your recipes, and built a brand your customers trust. Then someone opens a package three days too early and finds discolored meat or wilted greens. Suddenly you’re fielding complaints, issuing refunds, and watching your reputation take hits on social media. Every food producer faces this nightmare scenario at […] Learn More

-

How to Scale Your Production with Multi-Lane Tray Filling Systems

Have you ever watched your production line in action and wondered, despite their best efforts, if there was a way to get more done without overloading your staff or sacrificing product quality? That nagging question of efficiency is one that every food manufacturer, cosmetic producer, or pharmaceutical packager faces at some point. Scaling production isn’t […] Learn More

-

How to Choose the Best Cup Filler for Viscous, Dry, and Liquid Products

Have you ever stood in a grocery store aisle staring at perfectly sealed cups of sauces, neatly packed ready meals, or neatly portioned dry goods, and wondered how they get from a bustling production line into such a clean, uniform package? It looks effortless, but behind that polished presentation is advanced technology that businesses depend […] Learn More